One of the unique and extraordinary mega science festival — India International Science Festival (IISF 2023) is being organized during 17-20 January 2024 in Faridabad, Haryana. During the second day of this science festival on 18 Jan 2024, the Know-How Technology on “Bamboo Composites” was transferred to a well-known materials manufacturing company, M/s Asili Bamboo Products, Meerut, in the presence of Dr. Avanish Kumar Srivastava, Director, CSIR-AMPRI, Bhopal, and Mr Akshay Joshi, Director, M/s Asili Bamboo Products, Meerut. On this occasion various other dignatries were also present, namely Mr Md. Ali Shah, Sadhana; Dr. C. Anandharamakrishnan, Director, CSIR-NIIST Trivandrum; Prof. Manoranjan Parida, Director, CSIR-CRRI, New Delhi; Dr. B. Chandrasekaran, Former Director, CSIR-CLRI; Prof. Sudhir Singh Bhadauria, Director, UIT RGPV Bhopal; Shri Mayank Mathur, RC Member from CSIR-Headquarter; Dr. J.P. Shukla, Chief Scientist; Mr. Somnath Mazumder, CoA; Dr. J.P. Chourasia, Head PPD, CSIR-AMPRI; Dr. Sandeep Singhai, Head Business Development; Dr. Sarika Verma, PI and Principal Scientist; Dr. Neeta V.M. Khalkho, Sr. Principal Scientist, CSIR-AMPRI; and Dr. Satanand Mishra, Principal Scientist, CSIR-AMPRI, Bhopal.

Know-How Technology Transfer of “Bamboo Composites” on 18 Jan 2024 to M/s Asili Bamboo Products, Meerut, in the presence of Dr. Avanish Kumar Srivastava, Director, CSIR-AMPRI, Bhopal and Mr Akshay Joshi, Director, M/s Asili Bamboo Products, Meerut along with other dignitaries.

The industrial product, bamboo composites, has been developed using environment friendly technique by natural and versatile resource bamboo. Bamboo has been declared as grass and it proliferates rapidly with no stringent rules and regulations imposed for its growing, cultivation, propagation and cutting. Within 3-4 years, the bamboo gets matured can be utilised for developing into bamboo composite, unlike teak wood, which requires 30-40 years to grow. Bamboo is also an excellent absorber of CO2 and releases oxygen in large amount (approximately 35%) which helps to cure global warming. The bamboo composite product resembles teak wood with better durability & dimensional stability, high strength, density, mechanical strength, fire resistance, moisture resistance, and natural & aesthetic appearance.

The technology of manufacturing bamboo composites, developed by CSIR-AMPRI, has sequential steps like cutting of bamboo poles to desired sizes, splitting to strips, removal of knots, chemical treatment for protection against microbial/natural degradation, its conversion to fibrous form without damaging the natural strength of bamboo fibers, coating of adequate pre-polymer, which is followed by compaction under appropriate heat and pressure to obtain a composite sample of the desired shape. The final shape may be a moulded article, plain sheet, thick boards, beams, etc. These shapes can be further machined for the final finished product.

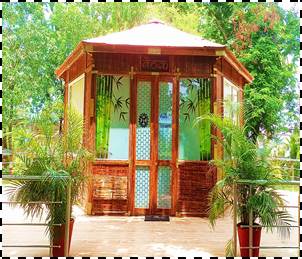

After the successful trials at industrial level, panel boards, beams, pillars, partitions, doors, window frames, roof, floorings etc., were developed, and a “Demonstration Structure (AMPRI’s Bamboo Composite Committee Room “Baithak”),” made up of bamboo composites has been erected in the campus of CSIR-AMPRI Bhopal in January 2022. It has a hexagonal base erected with a Peak height of 13’ 8”, a Max span of 24’8”, and a Floor area of 253 sq. ft. It includes walls, roofs, floors, beams, poles, doors, and window frames of bamboo composites. Using AMPRI’s bamboo composite technology recently, a similar structure has been erected at CSIR-NEIST, Jorhat, Assam.

Bamboo “Baithak” at CSIR-AMPRI and CSIR-NEIST

Inside View of Bamboo “Baithak” at CSIR-AMPRI, Bhopal

Due to its unique characteristics, the developed bamboo composite be can also used in various other sectors, especially in Aerospace. Therefore, bamboo can create future products similar to wood with a ten times faster harvest cycle, and with the growth in farming and cultivation of bamboo, the generation of employment, especially in rural areas will be improved. The technology have the potential to attract and encourage micro, small and medium enterprises, start-ups, etc., and thus, supports in achieving sustainable goals by contributing to Aatmanirbhar Bharat, Swasth Bharat Abhiyaan, Swachh Bharat Abhiyaan.

****

SNC/PK